Industrial IoT (Internet of Things) projects are widely popular in the manufacturing industry, having spent $178 billion on IOT in 2016 according to the International Data Corporation. Historically, the manufacturing industry has been one of the industries most reliant on IoT, and it is projected to remain so for the foreseeable future, until at least 2020.

The reasons behind the manufacturing industry’s reliance on IoT projects are multiple, but really have much to do with simple history: This is the way the industry has functioned for a while now. It’s just the way things are done. Manufacturing is also projected to continue to grow in size and spending in the near future, so IoT is necessary for an “Industrial Revolution 2.0.” Lastly, IoT´s ability to cater to manufacturing-specific needs only strengthens the relationship between its history and its future.

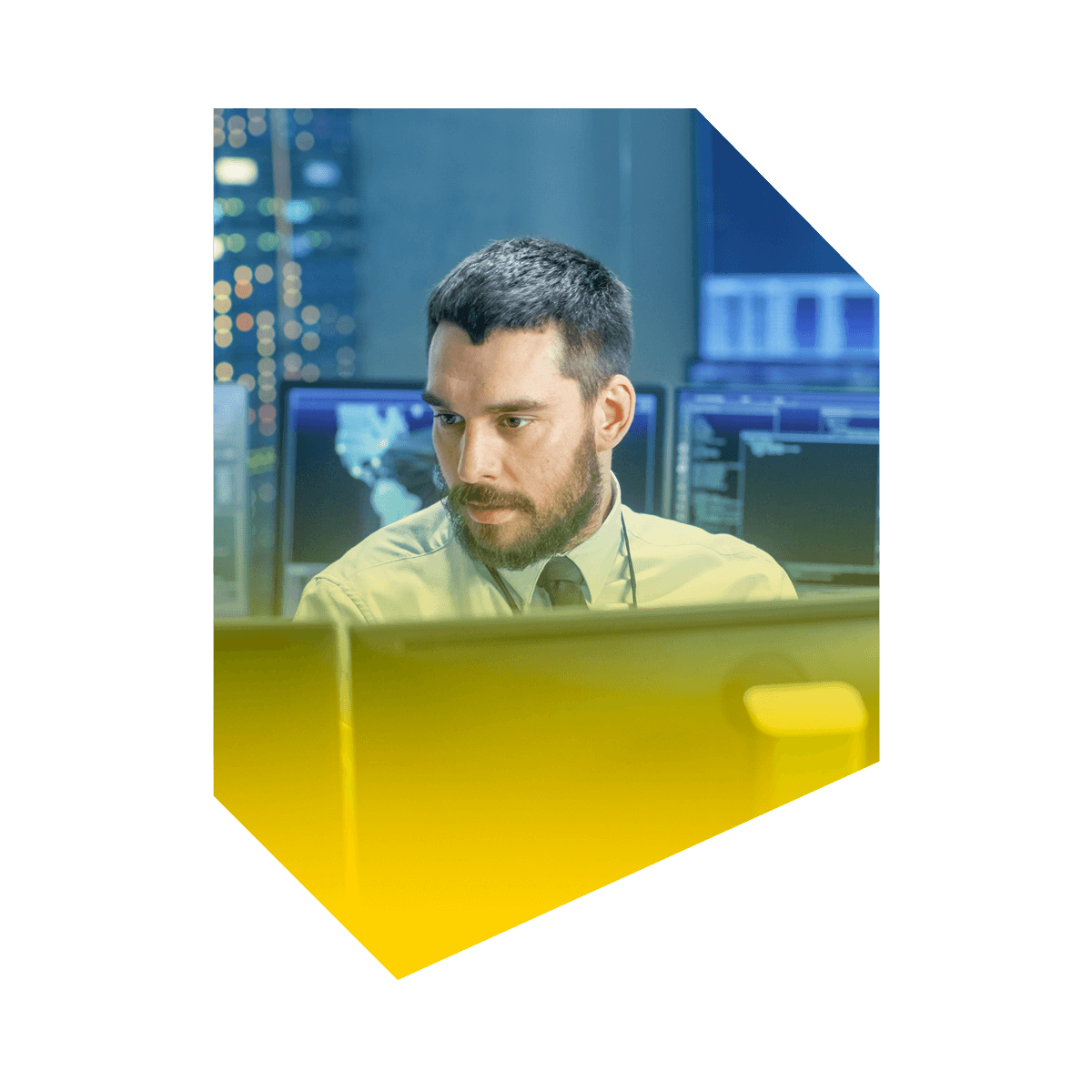

Human-machine interaction, asset management, and performance optimization are all crucial to manufacturing operations. So, IoT is recognized as a powerful and necessary tool to link the various, interconnected facets for smooth transactions. The network that allows these subcategories to communicate with one another is vast and it is only going to increase in size, popularity, and necessity as time goes on. In fact, this where most IoT spending takes place (57 percent of total IoT spending according to IDC numbers).

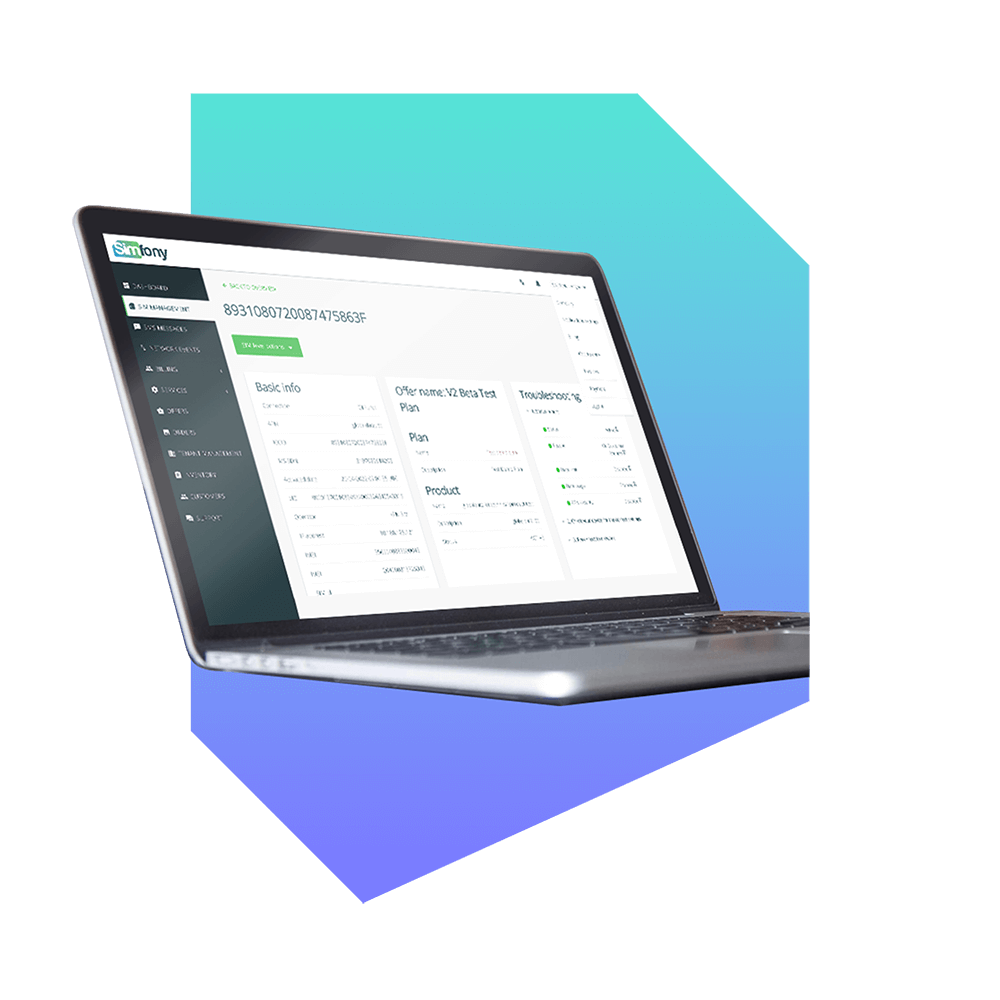

Service providers are also a substantial IoT spending category for the manufacturing industry. Both of these fields are very important due to their ability to create growth in the industry. IDC foresaw the manufacturing industry spending $183 billion in 2017 — an increase of almost 3 percent from the previous year. Manufacturing asset maintenance is also an extremely large IoT use case for this industry. In this category businesses oversee potential breakdowns, performance, and quality control with the goal of optimizing these parameters.

Workers in manufacturing are also an integral part to the industry’s success. This means that their safety and security should always be a top priority. When workers´ safety is linked with their transport and supply management, this connection becomes a huge opportunity for expanding the scope of IoT in day-to-day operations.

There is an obvious, cohesive, link between production, quality control, shipping, transportation, and the role an end customer plays in each transaction. Within each use case, there is a chain of data sharing that begins with the manufacturer and extends all the way to the customer. For a manufacturer to know how its product is viewed by its customers, there has to be a constant flow of feedback between the both parties. This is where IoT comes in.

IoT bridges the gap from the manufacturer to the warehouse, the warehouse to the extended supply chain, and finally the extended supply chain to the customer. The singular purpose of this astoundingly large data flow: Optimization.

Data that travels via the IoT bridge allows every party to know how it can improve its performance each step of the way. This is key to the industry’s success. Of course, in an age when almost all data is in “the cloud,” digitization cannot be ignored. Manufacturers rely on this data to keep open all lines of communication between a production factory and the services it supplies to its customers.

In 2015, IDC released some numbers that give a better sense about where the bulk of the effort associated with integrating IoT into the manufacturing industry is concentrated. The top contender was efficiency operations and the runner up was “the linkage between the islands of automation.”

In an attempt to demonstrate the measurable benefit of the use of IoT in the manufacturing industry, here are a few optimistic numbers provided by BI Intelligence:

When it comes to the hardware, software, services, and connectivity associated with IoT alone, BI intelligence estimates that global manufacturers will spend $70 Billion by 2020.

BI also proves that IoT solutions have a history of increasing revenue. Between 2013 and 2014 an average revenue increase of 28.6 percent was recorded by this type of manufacturer.

The Internet of Things has already shown us how it can positively impact the manufacturing industry and its foreseeable impact in the future is sure to be even greater than its current hold based on the proliferation of technology and big data in a myriad of industries.